In recent years, use of fiber optic technology has overtaken copper in data centers. Fiber allows for higher speeds and longer distances. However, fiber connections are highly sensitive to dust, and the condition of the connectors is of much more importance than when working with copper. It is of utmost importance to ensure your fiber optic equipment is in pristine condition when it is installed. This will limit the amount of connectivity issues in your fiber network, thus optimizing your data center installation’s time and cost efficiency. Also, if you want to know more about your data center being environment-friendly, then take a look at this article.

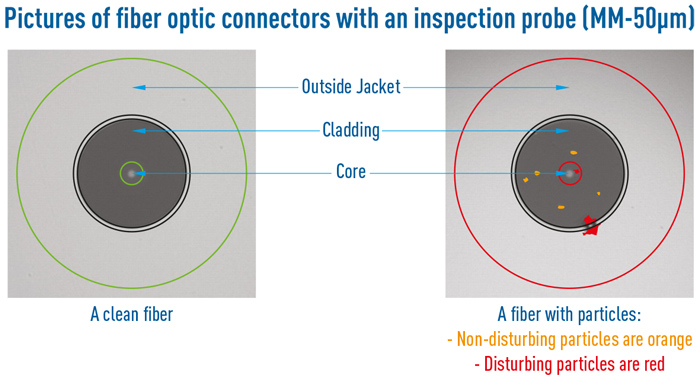

Dust, invisible to the naked eye, is the main culprit in fiber optic signal disruption. Depending on the size of the particle and where it is located, your signal could be slightly disturbed, but it could also result in complete signal loss. Say you are using a core of 9μ, and there is a piece of dust of 3μ in the way, that’s already a loss of 1/3 of your signal’s strength. Together with other losses, this could mean exceeding your power budget.

Dust, invisible to the naked eye, is the main culprit in fiber optic signal disruption. Depending on the size of the particle and where it is located, your signal could be slightly disturbed, but it could also result in complete signal loss. Say you are using a core of 9μ, and there is a piece of dust of 3μ in the way, that’s already a loss of 1/3 of your signal’s strength. Together with other losses, this could mean exceeding your power budget.

In the vast majority of cases, simply cleaning the fiber is enough to reestablish the signal. Professionals not only ensure that connectors are clean before they plug them, they also make sure always to use dust caps when equipment is not in use. Dust caps are absolutely essential in keeping your fiber clean. The dust caps themselves must also be kept clean, so as to avoid transferring dust from the caps to the fiber.

There are two steps to maintaining immaculate fiber: cleaning the equipment, and inspecting the fiber. For cleaning, there are two ways to remove dust: dry and wet methods. Inspection is performed using a scope. The importance of cleanliness escalates as the diameter of the fiber narrows. Dust that is 3µ wide on a 9µ core (Single-Mode standard) causes a much greater loss of performance than in a 50µ wide core (Multi-Mode standard).

Tools for fiber inspection and cleaning

INSPECTION

1. Direct scopes

These microscopes feature a 100-400x zoom (depending on the model) and an internal light source. They are applied directly to the fiber connector in order to inspect the condition of the fiber strand. Direct scopes are affordable devices, with a price ranging between $70 and $250. They are not very versatile, however, as they can only inspect cables. Special adapters may be required for special connector types. Also, caution must be taken not to look directly into the beam.

2. Videoscopes

Videoscopes are the most effective way to inspect the condition of your fiber. They transmit the picture from the scope to a screen, for instant & easy assessment of the fiber’s condition. Standalone models transmit the picture to a handheld display, while USB models can transmit the picture to your laptop, and wireless models to your smartphone. Videoscopes are often accompanied by automatic analysis software, which provide quicker inspection, and validation against international standards. These devices range from $1000 to $2500.

CLEANING

3 & 5. Dry method

Compressed air and bulkhead ferrule cleaners (one-click cleaners)

One-click cleaners are an affordable and effective way to clean fiber connectors. Inserting the head into the adapter and pushing until the “click” removes dust by swabbing the fiber. Only the center of the fiber is cleaned, however. Patch cords can be cleaned in the same way, using the provided adapter. Bulkhead ferrule cleaners can be purchased for around $60 and used up to 500 times.

Compressed air assists in the cleaning of fiber. It is an effective way to clear connectors and dust caps of loose dust particles. At around $8 per 400ml bottle, it is a must-have for fiber cleaning. After cleaning the fiber, it should be immediately connected, or clean dust caps should be inserted, in order to avoid further dust exposure.

4 & 5. Wet method

Sticklers’ CleanStixx™ and lint-free isopropyl alcohol wipes

Gently wiping fiber strands with these wipes is the most effective way to remove resistant dust particles, oil, or other contaminants. When the dust and isopropyl alcohol make contact, the dust is pulled into the alcohol, and the wipe clears both the dust and liquid from the fiber surface.

Sticklers’ CleanStixx™ have been designed to take over from the wipes when a device is already installed in a rack. They also come in different versions which allow them to adapt to any connector and size.

A box of lint-free wipes costs around $10, and a bottle of isopropyl alcohol will cost about $7. For field service engineers, pre-moistened wipes can be purchased for $10 for 50 wipes. The CleanStixx™ price range spreads from $30 to $50 for 50 pieces. For faster drying, compressed air can be used.

6. Fiber Optic Connector End-Face Cleaning System

Major data center installations rely on these systems to cope with large-scale cleaning. They are advanced tools, which use an air-solvent-air process to quickly eradicate dust and contamination. They can also include a videoscope and video display for fiber inspection. Although they have a more expensive base price, at around $6000 for an entry level device, they are the most cost-effective per-clean solution on the market.

Profitap’s 4-Link LC Fiber Optic TAP

Fiber optics need to be installed in perfect condition for optimal performance. It is definitely not as much of a “Plug and Play” technology as it may seem, as it requires thorough cleaning and inspection before it can be utilized. The good news is, Profitap’s Fiber TAPs are guaranteed to be in pristine condition from the moment they are manufactured, all the equipment being tested, inspected and cleaned multiple times before shipment.

For more on network TAPs, check out "Exploring the Different Types of Network TAPs" article.